World class capability in

Machining.

The largest and most proven contract machine shop in NZ.

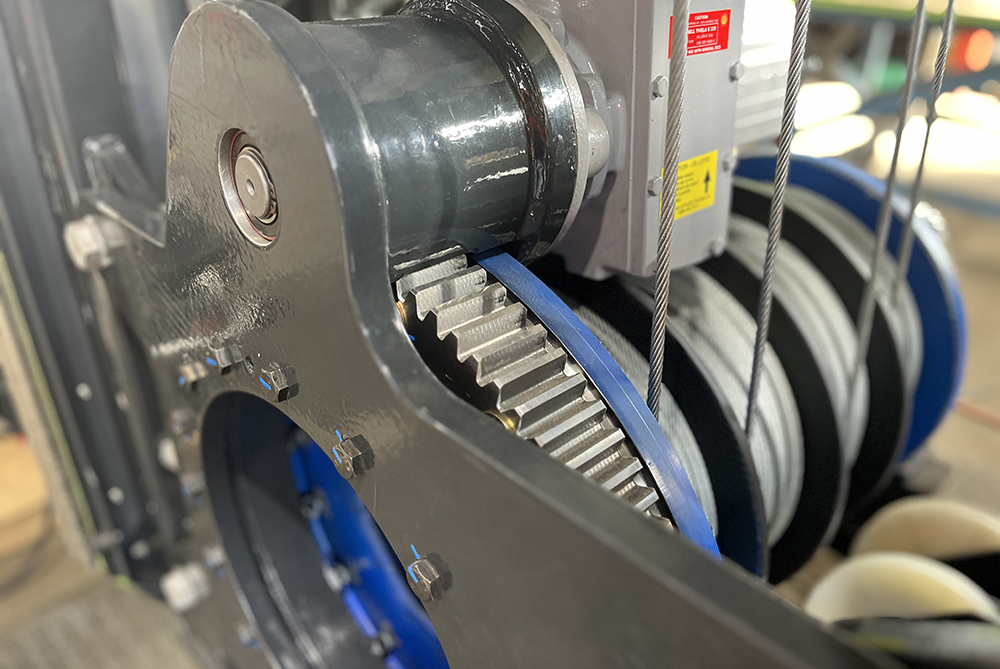

OUR MACHINING TEAM OFFER PRECISION MACHINING AND AND SITE SERVICES TO THE ENERGY SECTOR AND HEAVY INDUSTRY.

Our machinery includes CNC turning, CNC horizontal boring, multi-pallet HMC’s, large capacity turning and milling, surface grinding, and a range of other machines to service any requirements. This is complemented by a very experienced team of tradespeople who truly understand material behaviour. Our heavy precision machining, CNC Pallet machine, our vertical lathe and horizontal machining centres are some of the largest in the country. We are recognised for our CNC production capability with multi-pallet machines delivering the highest levels of repeatability and efficiency.

EQUIPMENT & WORKSHOP

Our extensive range of huge, specialist heavy machining equipment and lifting capabilities to 32 tonnes enables us to deliver the high level of accuracy, reassurance and responsiveness required to support New Zealand’s Power Stations safely.

- CNC vertical lathes with up to 9m max turning diameter and unique attributes that allow large items up to 4m diameter by 5m tall to be turned in the vertical axis.

- CNC horizontal boring / milling machines thorough to a machining envelope of 8.6m x 3.5m with rotary table

- CNC vertical and horizontal machining centres – 3, 4, and 5-Axis with full contouring, 8 Pallet capacity and 1400 x 1200 Y 1000mm Z envelope, ideal for production work and lights out operation.

- Horizontal manual lathes that can accommodate up to 30 tonnes unsupported and centre-to-centre distances up to 7 metres. Or up to 20 metres with steady rests.

- CNC horizontal lathes form small bar feed, through to 1200mm swing.

- Surface grinding

2m x 0.7m x 0.4m rectangular items.

1.8m diameter x 1.0m tall items up to 4 tonne. Most shapes within this envelope can be accommodated.

OUR ACCREDITATIONS

We take pride and have invested heavily in the quality systems, accreditation, assurances, equipment, and expertise, required for heavy fabrication. For further info on quality plus our weld certification and procedures, see our Quality Systems.